Medical Catheters and Plastics – Part VI

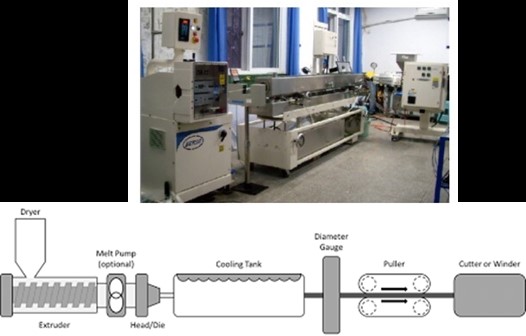

In the initial segments of this series, we examined the characteristics of catheters, ranging from their physical attributes to their surface features. We will now turn our attention to the manufacturing process of medical catheters. The production of catheters employs thermoplastic melt extrusion utilizing dies specifically designed to create circular cross-sections. Catheters can essentially be regarded as miniature versions of pipe and hose manufacturing; however, this process is not merely a reduction in scale and encompasses various factors essential for successful production. This blog covers two components of a catheter extrusion line, with additional components to be discussed in future articles.

Extruder

In the production of medical catheters, single screw extruders with screw diameters of 1" (25.4 mm) or smaller are preferred due to the low output associated with the manufacturing of small diameter tubes. The extruder functions as a melting and pumping device, transforming solid plastic pellets into a consistent polymer melt. This melt is subsequently pushed through a tubular die at a steady rate. The frictional heat produced from the mechanical action of the screw, along with heat transferred from the heated barrel of the extruder, provides adequate heat for melting the material. The length of the extruders and the design of the screw depend on the type of material being processed. Longer extruders and complex screw designs are unsuitable for shear-sensitive materials, as excessive shear can lead to degradation, which is characterized by a decrease in the polymer's chain length and a consequent reduction in the mechanical properties of the tubing. Shear rates are influenced by the screw design, the revolutions per minute (rpm) or speed of the screw, and the clearances within the die. Additionally, the inclusion of fillers affects the considerations for screw design; for instance, radio-opaque fillers like Bismuth-based compounds are typically shear-sensitive. Many tubing production lines incorporate a melt pump, where the gear-based melt pump serves as the primary mechanism for flow control.

The degradation of polymers significantly impacts the characteristics of the final catheter; any decrease in chain length leads to a deterioration of the catheter's mechanical properties, and in severe instances, the catheter may become entirely discolored and brittle. There are multiple sources of chain degradation. Excessive shear, as previously discussed, can result in degradation. A comparable effect may arise from utilizing an incorrect temperature; excessively high temperatures can induce degradation due to heat, while excessively low temperatures may elevate shear rates to a level sufficient to cause shear-induced degradation.

Dryer

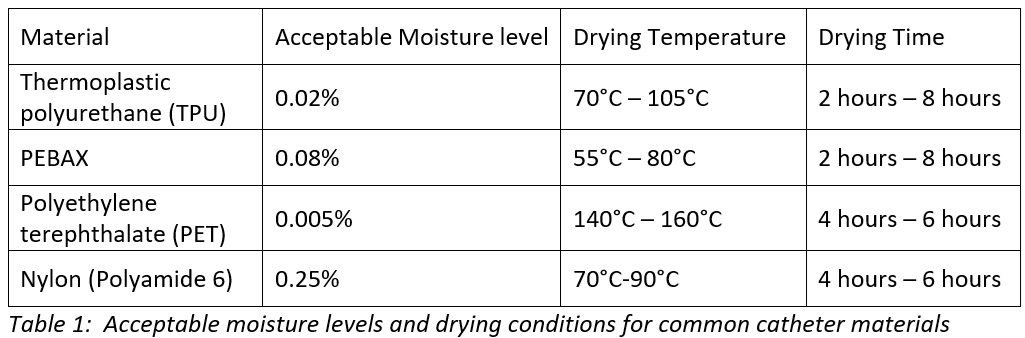

The presence of moisture within the extruder can result in the degradation of certain materials; polymers such as thermoplastic polyurethanes and polyethylene terephthalates are particularly susceptible to depolymerization when moisture is present, especially at elevated temperatures. Consequently, drying polymer pellets, which is often the initial step in most extrusion processes, is a crucial phase in catheter extrusion. Within the dryer, hot dry air is introduced at the bottom of the hopper that contains the resin, allowing it to flow upward through the pellets and effectively removing moisture along its path. The hot, moist air exits from the top of the hopper and is initially directed through an after-cooler, as it is more efficient to extract moisture from cooler air than from hot air. The resulting cool, moist air is subsequently passed through a desiccant bed. Ultimately, the cool, dry air that emerges from the desiccant bed is reheated in a process heater and recirculated through the same procedures in a closed-loop system. The extent of drying is significantly influenced by the type of material utilized in the extrusion process. Insufficient drying of certain materials may lead to degradation within the extruder, while excessive drying may result in thermal degradation of other materials. The drying specifications for various plastics are typically determined by the manufacturer of the plastic.

Some general drying conditions are stated in Table 1:

The moisture level must be measured accurately to meet the material specifications. Various methods are available for assessing the moisture content in plastic materials. The techniques for determining moisture content include loss of weight, chemical reaction, thermogravimetric analysis, and spectroscopic tests. The loss of weight method, also known as the loss on drying (LOD) technique, along with the chemical reaction method of titration, are commonly employed for plastics. When the volatile component of the solid is predominantly water, the LOD technique provides a reliable estimate of the moisture content. In a standard LOD analyzer, the sample is positioned on a sensitive balance within the device, after which it is quickly heated, and the moisture content is gauged as the sample weight decreases due to moisture release. A more precise approach for quantifying water content is the Karl Fischer (KF) titration method. This technique, developed in the 1930s by German chemist Karl Fischer, relies on the interaction of water molecules with the KF titrant and the resulting electrical activity. The KF method offers high accuracy and precision, and unlike the LOD technique, it is specifically selective for water rather than other volatile substances.

If you have any other questions or would like to suggest topics for us to write about, please feel free to contact us at info@polymerupdateacademy.com

Author

Mr. Ajay D Padsalgikar, (Ph.D. - California, USA)

Trainer at Polymerupdate Academy