Industrial Applications of Polymer Composites

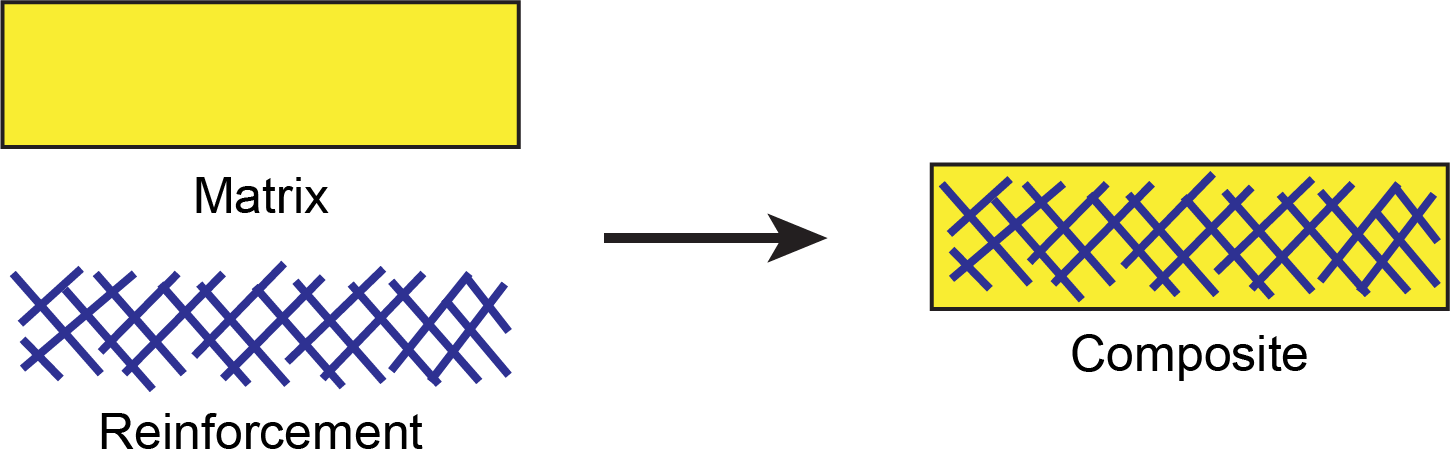

A polymer composite can be defined as a three-dimensional amalgamation comprising, at the very least, a filler of either organic or inorganic nature, dispersed within a continuous or co-continuous phase of an individual polymer or a blend of polymers. The inclusion of polymers and fillers in various blends can be strategically employed in diverse combinations to surmount the limitations inherent to individual components, thus achieving the desired properties essential for industrial products. The versatility of polymer composites, ingrained in their potential to attain a specific set of desired characteristics encompassing mechanical, chemical, physical, electrical, electrochemical & biological attributes, and are tailored to meet requisites such as processability, dimensional stability, thermal properties, and cost-effectiveness. This has paved the way for the widespread application of polymeric composites across a plethora of industries which encompass construction, packaging, tissue engineering, energy storage, sensors, transportation, and beyond, with the utilization of polymer composites in industrial contexts consistently expanding over time. With the emergence of advanced and novel technologies concerning the formulation of individual components and composites, an assortment of material combinations has piqued the interest of both industry and academia. In response to consumer demands, the primary focus of industrial research has shifted towards not only the development of new materials but also the exploration of fresh applications for existing materials.

The polymer composites have proved their efficacies in various industries due to their remarkable properties and versatility. These advanced materials, composed of a matrix polymer reinforced with fibers or fillers, have found their way into numerous industrial applications. From enhancing the strength of structural components in construction to improving the efficiency of energy generation and storage systems, polymer composites are driving innovation and reshaping industries across the board. This article explores diverse applications of polymer composites across varied industrial sectors including construction, packaging, tissue engineering and biomedical, energy generation and storage, fuel cells, sensors, automotive and logistics, and more.

Construction Industry

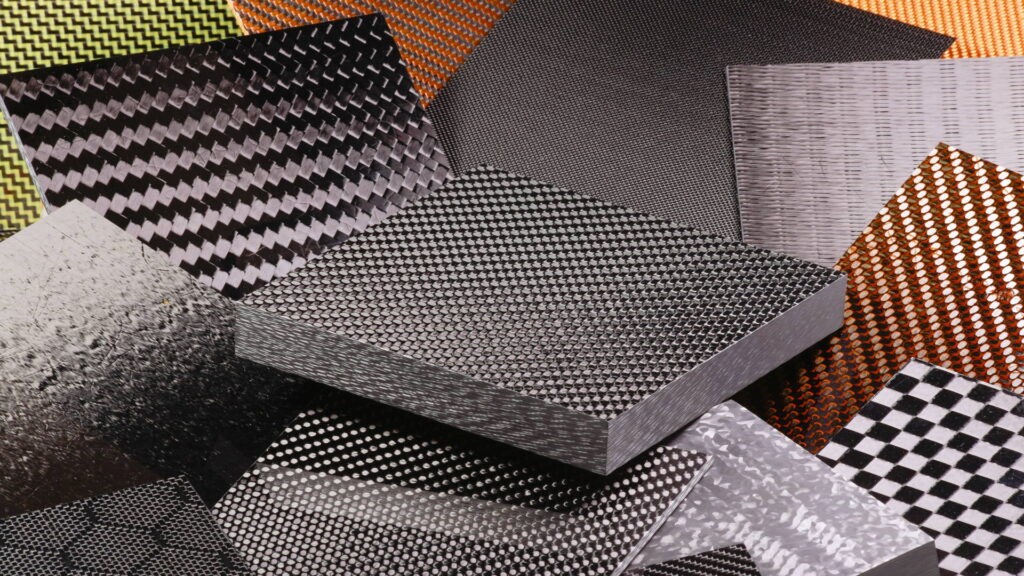

- Reinforced Concrete: Polymer composites, such as carbon fiber-reinforced polymers (CFRPs) and glass fiber-reinforced polymers (GFRPs), have become indispensable in the construction industry. They enhance the strength and durability of structures while reducing weight. CFRP, for example, is used to reinforce bridges, tunnels, and buildings, extending their lifespan and reducing maintenance costs.

- Composite Panels: Lightweight, corrosion-resistant composite panels are employed in cladding and roofing systems, providing weather protection and insulation. Their excellent thermal and acoustic properties contribute to energy efficiency and comfort in buildings.

FRP Rebars

Packaging Industry

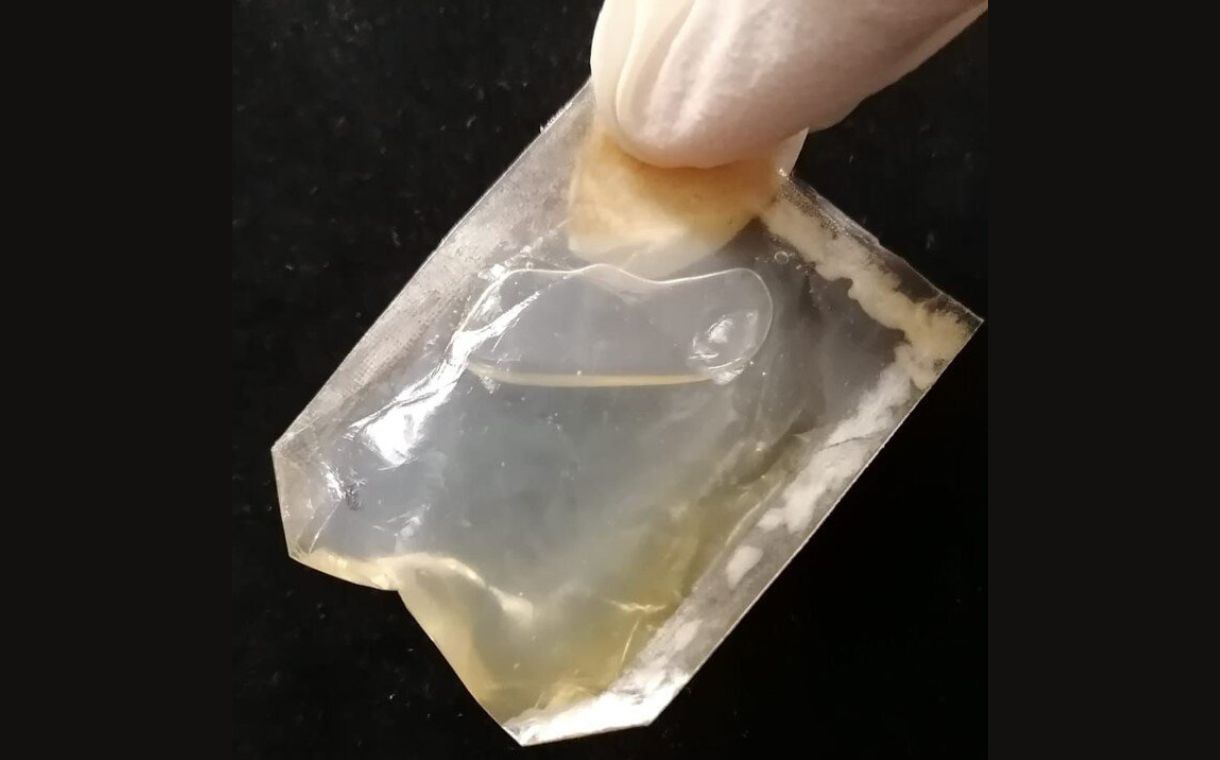

- Lightweight Packaging: The packaging industry benefits from polymer composites by utilizing their lightweight and durable properties. Composites are used in packaging materials to protect goods during transport while reducing packaging waste.

Edible composite packaging made from cellulose (Image reference: https://phys.org/news/2023-06-edible-transparent-composite-packaging-biocellulose.html)

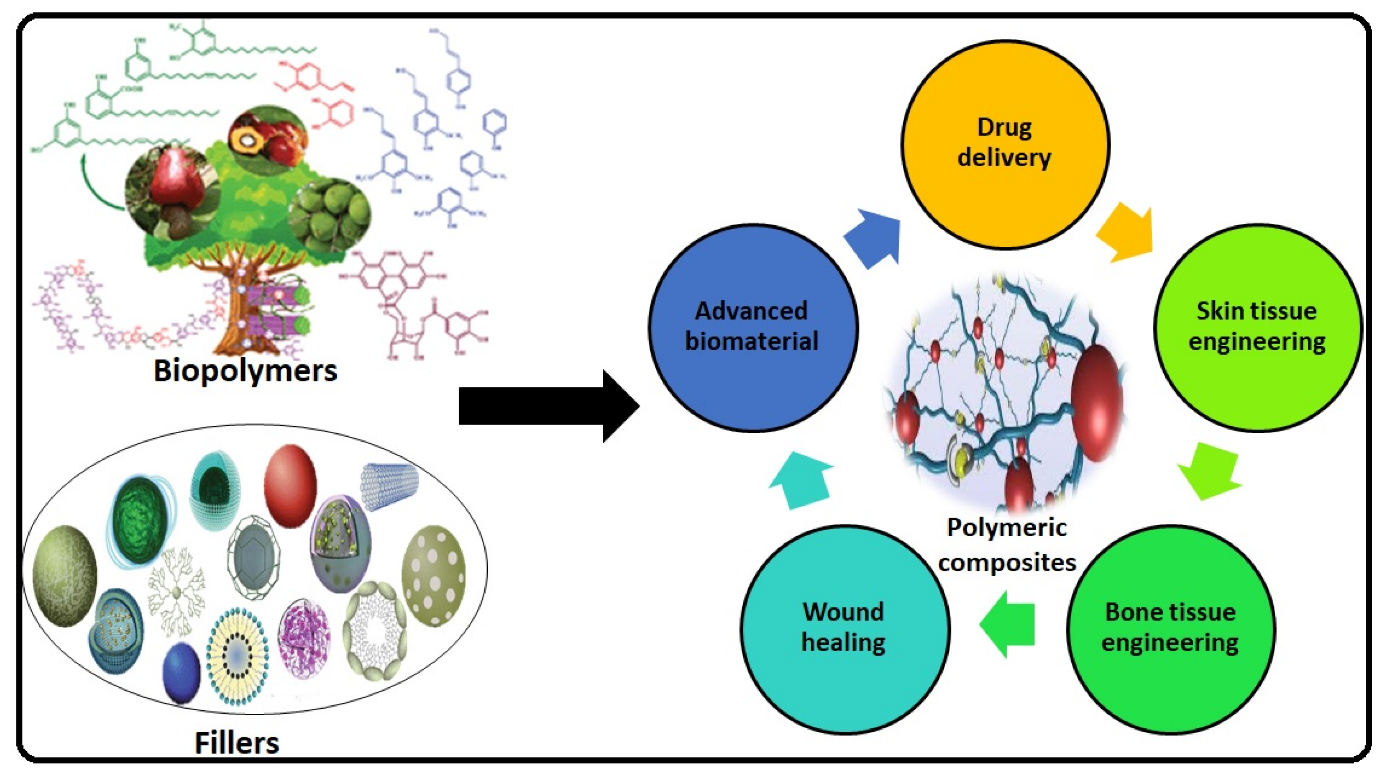

Tissue Engineering and Biomedical Applications

- Implants and Prosthetics: Polymer composites play a pivotal role in the development of medical implants and prosthetic devices. Materials like biocompatible polyethylene and polyurethane composites ensure compatibility with the human body, improving the quality of life for patients.

- Tissue Scaffolds: Specially designed composite materials serve as scaffolds for tissue engineering, promoting the regeneration of damaged tissues and organs. These scaffolds mimic the mechanical properties of natural tissues, aiding in the healing process.

Applications of polymeric composites in biomedical engineering (Image Reference: https://www.mdpi.com/1420-3049/26/3/619)

Energy Generation and Storage

- Wind Turbine Blades: Composite materials, such as fiberglass and epoxy resins, are commonly used in the manufacture of wind turbine blades. Their lightweight and strong nature makes them ideal for harnessing wind energy efficiently.

- Lithium-ion Batteries: Polymer composites are integral to the development of high-performance lithium-ion batteries. They enhance the battery's capacity and cycle life while reducing weight and increasing safety.

Fuel Cells

- Proton Exchange Membranes (PEMs): Polymer composites are essential in fuel cell technology, particularly in PEM fuel cells. These membranes facilitate the conversion of hydrogen into electricity, and their durability and conductivity are vital for efficient energy generation.

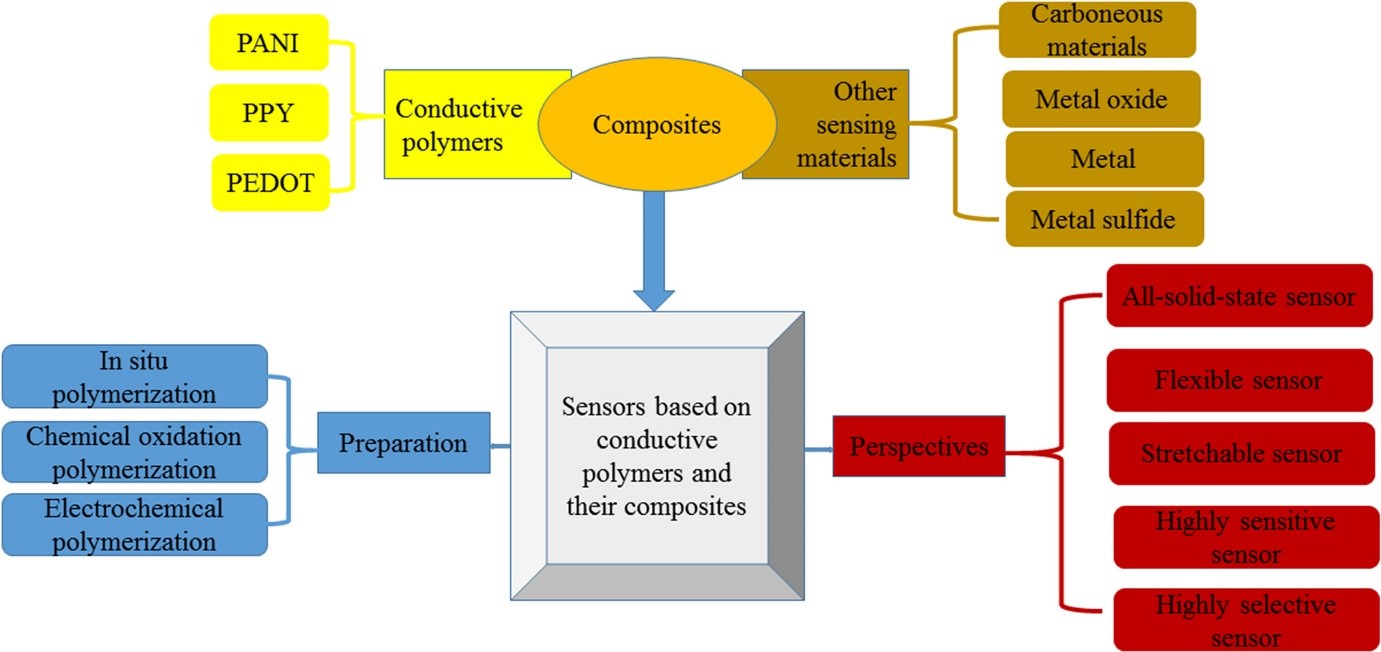

Sensors

- Chemical and Environmental Sensors: Polymer composites are utilized in the production of chemical and environmental sensors due to their sensitivity, durability, and adaptability. These sensors monitor air quality, water quality, and industrial processes, enhancing safety and efficiency.

Scheme for sensors based on polymer composites (Image Reference: https://onlinelibrary.wiley.com/doi/abs/10.1002/pi.5907)

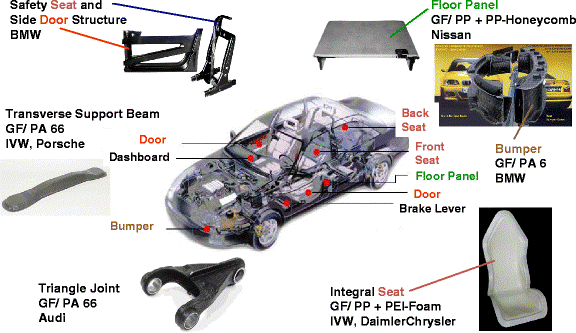

Automotive and Logistics

- Lightweight Automotive Components: The automotive industry benefits from polymer composites through the production of lightweight components. Lightweight materials reduce fuel consumption and emissions while maintaining structural integrity.

- Cargo Containers: Composite materials are used in the construction of cargo containers for shipping and logistics. They are not only lightweight but also durable, ensuring the safe transport of goods across the globe.

Advanced composites in the automotive sector, Reference: https://link.springer.com/article/10.1007/s10443-012-9258-7

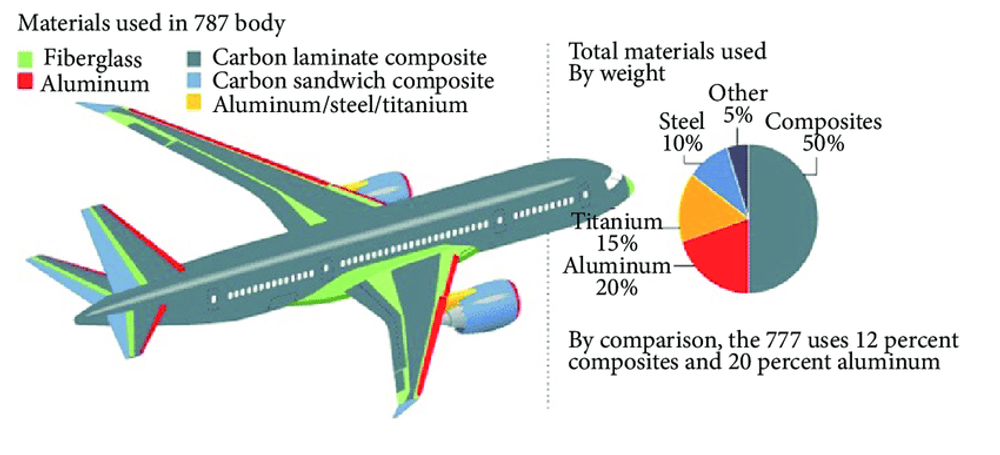

Aerospace

- Aircraft Components: The aerospace industry relies heavily on polymer composites for their exceptional strength-to-weight ratio. These materials are used in aircraft components such as wings, fuselages, and interior panels to reduce weight and increase fuel efficiency.

Composites in Boeing 747 industry (Reference: https://www.addcomposites.com/post/where-are-composites-used)

Electronics

- Printed Circuit Boards (PCBs): Polymer composites are used in PCBs to improve their thermal and electrical properties. Advanced composites offer higher performance, enabling faster and more efficient electronic devices.

In a nutshell, the field of construction has undergone a significant transformation with the introduction of polymer composites. The adoption of multi-layered laminar composites has empowered civil engineers to substitute a considerable portion of heavy concrete, addressing the pressing need to reduce overall construction weight. This innovation has paved the way for the creation of highly durable and lightweight structures. In the realm of packaging, polymer composites have made substantial contributions. The incorporation of multi-layered films, each of which is a composite in itself, has provided packaging experts with the means to precisely control the permeability and diffusivity of various harmful environmental gases. As a result, the shelf life of packaged contents has been significantly extended. Furthermore, the development of semi-permeable membranes, a critical component of microbial fuel cells, has made remarkable progress thanks to the involvement of polymer composites. These materials have played a pivotal role in advancing this technology. In the automotive sector, the production of various devices and accessories would have been virtually impossible without the utilization of polymer composites. Polymer composites have revolutionized numerous industries, offering a unique combination of lightweight, strength, durability, and adaptability. From the construction of resilient structures to the development of life-enhancing biomedical devices, these materials continue to drive innovation and improve the quality of life for people worldwide.

If you have any other questions or would like to suggest topics for us to write about, please feel free to contact us at prashant.gupta@polymerupdateacademy.com

Author

Dr. Prashant Gupta

Faculty, Polymerupdate Academy