Precision in Strength: Exploring Extensometers in the Plastic Industry

In the plastic industry, product quality and performance are reliant on the mechanical properties and strength of plastic materials. Strength testing forms a crucial factor in evaluating the feasibility of plastic materials for different purposes. The extensometer is a key device used in strength assessment. In this blog post, we'll look at the importance of extensometers and how the plastics industry uses them to gauge material strength.

Extensometers are precise instruments used to monitor changes in a specimen's length or deformation throughout a mechanical test. Typically, it is a strain measurement device which is employed to measure the extension of a material under various types of loads. When a load, like the pulling force involved in tensile testing, is applied to a material, it will physically deform, known as extension. Additionally, extensometers aid in determining compressive deformation or deflection under various load applications, such as cyclic tests (including fatigue tests), compression tests, and flexure tests, in addition to strain brought on by tensile loads. It offers precise and trustworthy information on a material's elastic and plastic properties, enabling manufacturers to assess its strength qualities. Plastics are known for their viscoelastic nature, which means they exhibit both viscous (fluid-like) and elastic (solid-like) behavior when subjected to stress or strain. Unlike purely elastic materials, such as metals, plastics have the ability to deform over time under a constant load or exhibit time-dependent deformation when subjected to varying loads.

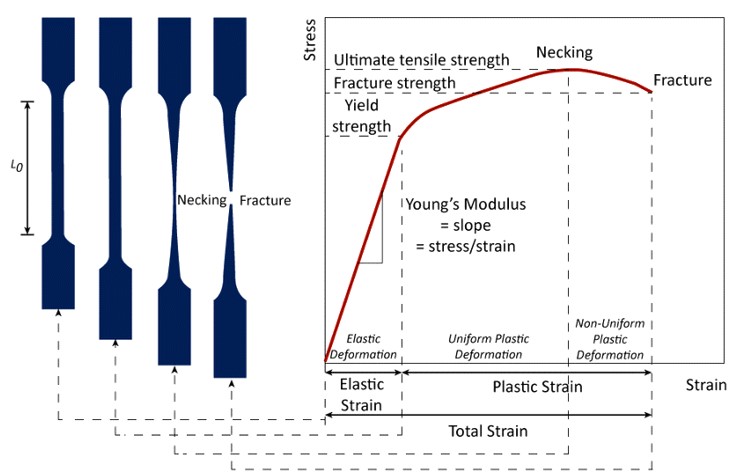

Figure 1. A typical stress strain curve for plastic materials

When we analyze typical stress-strain curves of plastics as given in Fig.1. we observe that they do not necessarily follow a long straight line as seen in purely elastic materials. Instead, the stress-strain curves of plastics often exhibit nonlinear behavior. This nonlinearity is a result of the combination of viscous flow and elastic deformation that occurs within the material. At lower stress levels, plastics may exhibit elastic behavior, where the strain is directly proportional to the applied stress. This linear region is like the behavior observed in elastic materials. However, as the stress increases, plastics start to exhibit viscoelastic behavior, and the stress-strain curve deviates from linearity. In the viscoelastic region, the stress-strain curve may show time-dependent behavior, such as stress relaxation or creep. Stress relaxation refers to the gradual decrease in stress over time when the material is held at a constant strain while creep refers to the gradual increase in strain over time when the material is subjected to a constant stress. The nonlinear stress-strain behavior in plastics is attributed to various factors, including the presence of polymer chains with different relaxation timescales, molecular mobility, temperature, and rate of deformation. These factors influence the viscoelastic response of plastics, making their stress-strain curves more complex compared to purely elastic materials. Understanding the viscoelastic nature of plastics and the nonlinear stress-strain curves is crucial in engineering and designing plastic components or structures. It allows for a more accurate assessment of the material's mechanical behavior, accounting for time-dependent effects and ensuring the appropriate selection and application of plastics in various industries. Extensometers are incredibly helpful for evaluating plastic because they can exhibit unique behaviours under different stress conditions.

-

Finding Yield Strength: Yield strength is an important factor in plastic testing since it tells you how much stress a material can take before deforming plastically. Extensometers are used to measure strain, making it possible to precisely determine yield strength. Extensometers give useful information for analysing the yield behaviour of plastic materials by tracking elongation and changes in specimen dimensions throughout a tensile test.

-

Assessing Ductility: The ability of a substance to deform plastically without breaking is referred to as ductility. It is a crucial quality to assess in plastic materials because many applications call for flexibility and breaking resistance. Extensometers assist in measuring elongation and strain during tensile testing, making it possible to assess the ductility of a material. By quantifying the extent of deformation before fracture, manufacturers can assess the suitability of plastic materials for specific applications.

-

Modulus of Elasticity Monitoring: The Young's modulus, commonly known as the modulus of elasticity, is a fundamental mechanical characteristic of materials that characterises their stiffness and capacity to deform under stress. Extensometers measure the stress-strain relationship during a test to help determine the elastic modulus. Designers and engineers who need to understand how plastic materials will respond to various loads and deformations must have access to this information.

-

Characterizing plastic deformation: The specific behaviours that plastic materials display during deformation, such as strain hardening and strain softening, are known as plastic deformation characteristics. Extensometers, which continuously measure strain throughout a test, aid in the capture and analysis of these features. Manufacturers can use this information to understand how a material responds to stress and decide on the best material and processing conditions.

Clip Extensometer in action during tensile testing

Video Extensometer in action during tensile testing

Clip Extensometer in action during flexural testing

Extensometers play a vital role in the plastics industry, accurately measuring strain directly on specimens in various sectors. By eliminating potential measurement influences from other testing components, they enhance the accuracy and reliability of data. Measurement of strain is essential in determining characteristic values of materials, including tensile modulus, Young's modulus, yield point, strain at break, r-value, and Poisson's ratio. These values are instrumental in comparing materials and helping manufacturers assess their suitability for anticipated loads in specific applications. Extensometers demonstrate versatility across a wide range of industries and materials, including metals, plastics, fiber-reinforced composites, elastomers, films, textiles, ropes, paper, and wood. They provide valuable insights into the mechanical properties of tested materials, ensuring quality control and aiding in material selection for specific purposes. In the plastics sector, extensometers are particularly valuable for verifying the mechanical integrity of plastic materials during strength testing. By measuring elongation, strain, and deformation, extensometers gather crucial information on yield strength, ductility, elastic modulus, and plastic deformation properties. Manufacturers can leverage this knowledge to choose appropriate materials, develop products, and improve processes. As the plastics industry continues to evolve, extensometers will remain indispensable in ensuring the quality and performance of plastic goods across a wide range of applications.

If you have any other questions or would like to suggest topics for us to write about, please feel free to contact us at prashant.gupta@polymerupdateacademy.com

Author

Dr. Prashant Gupta

Faculty, Polymerupdate Academy